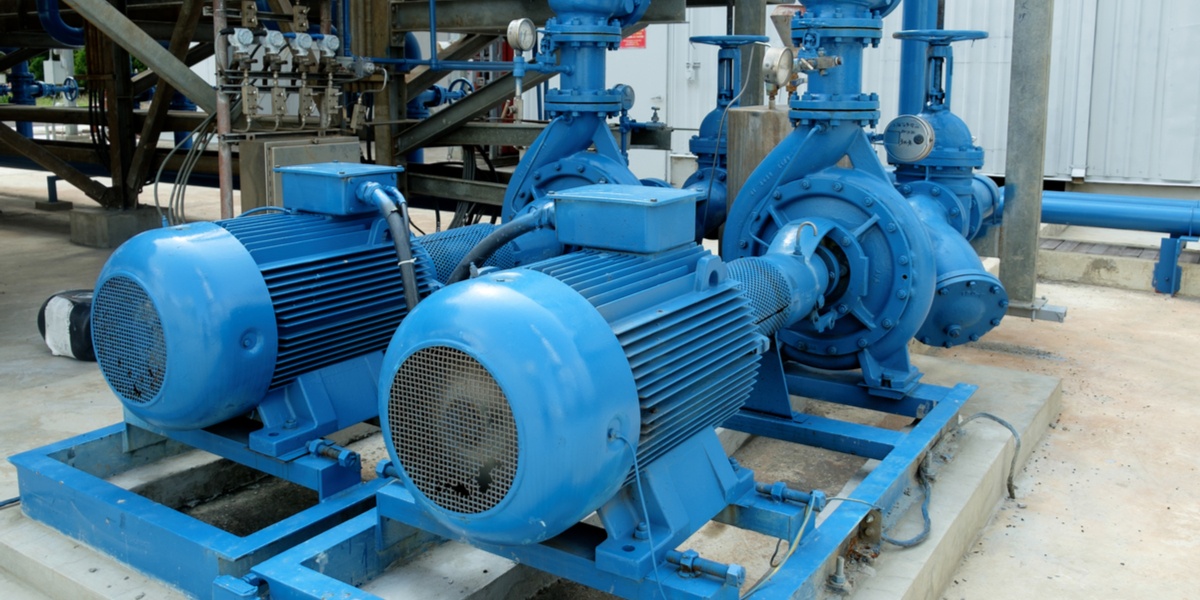

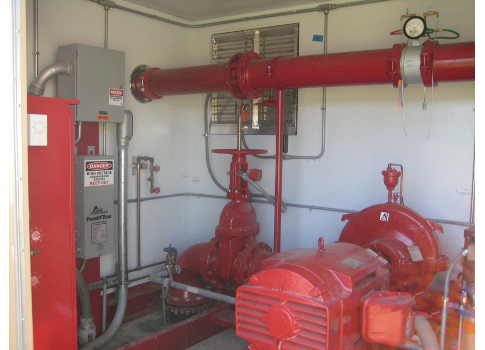

Identification Of Electrical Motor Pump Set

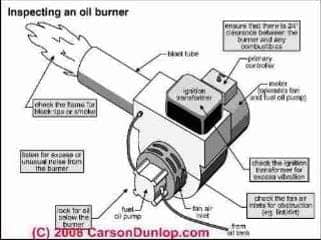

Where every diaphragm contains a set of ball or check valves.

Identification of electrical motor pump set. Three phase see below single voltage. Pump electric motor specifications require mechanical and electrical requirements. Motors have two barrel widths rated as either 48 or 56. Chuck yung easa technical support specialist one frequent request of easa s technical support staff is for help in identifying unmarked motor leads.

For specific leeson motor connections go to their website and input the leeson catalog in the review box you will find connection data dimensions name plate data etc. For most connections the only tools required for these procedures are an ohmmeter and surge tester. Note similar nameplate letter designations also represent other motor characterisitics. Exporter of electric pump sets motor electric motor dewatering submersible pump diesel engine driven pumpset and bore well submersible pump offered by industrial machinery agency mumbai maharashtra.

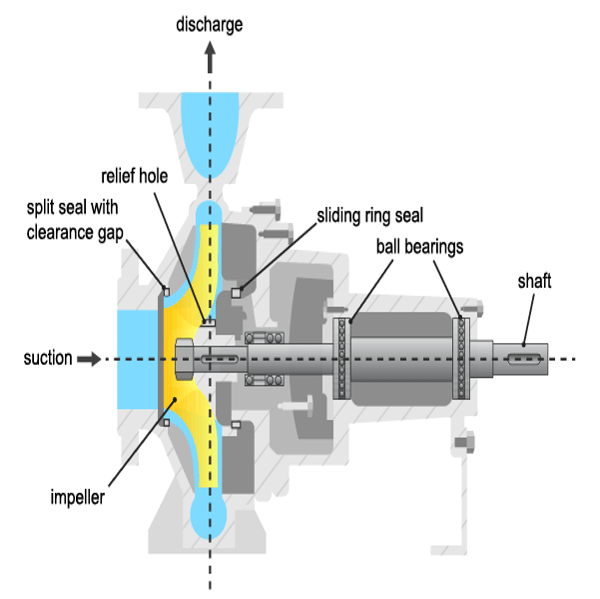

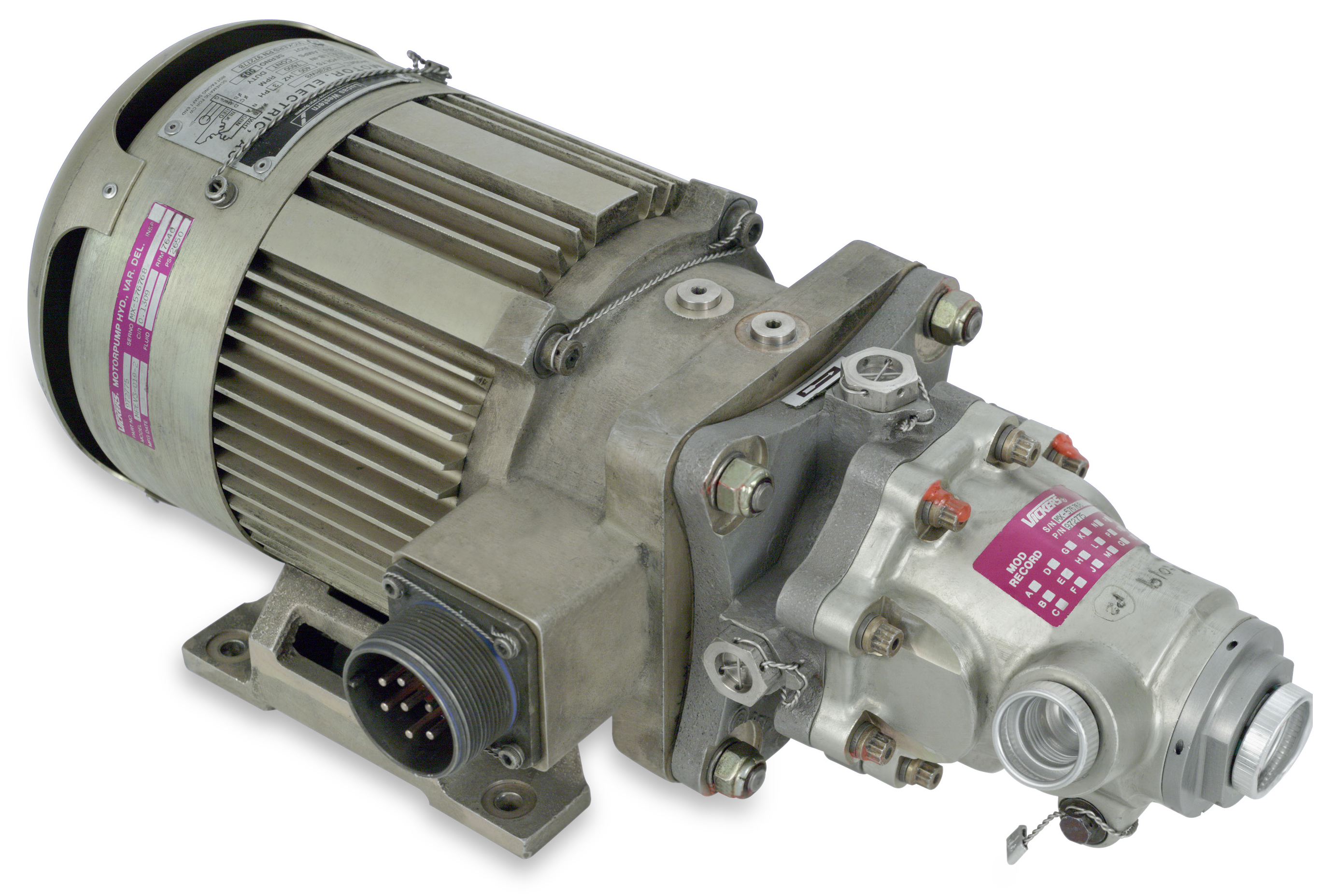

This article introduces a set of proce dures for identifying unmarked leads of 6 lead motors with 1 or 2 wind ings. This kind of pump produces an enhancement within force by transmitting mechanical power from the electrical motor to the liquid throughout the revolving impeller. For example if a small gear motor designed to operate at a max of 3 000 psi and 1 000 rpm is put into an application that requires it to run consistently at 3 000 psi and 1 000 rpm the motor will be running in a corner overstressed condition and. Full rated vs up.

Most mid range motors like the 1 and 1 5 hp motors are dual voltage that can run on both 115 or 230. A replacement motor with a higher code letter may require different upstream electrical equipment such as a larger motor starter. Generally the farther the code letter is from a the higher the inrush current per hp. Motors can vary in size depending upon power speed rpm frame size area classification orientation service factor and type of enclosure e g.

In addition this section contains important data covering internal wiring to motor terminals which will prove invaluable to the refrigeration service engineer in solving motor problems. Totally enclosed fan closure. For 2 hp motors and above those are strictly 230 voltage. Frame f motors have two distinct flange bolt pattern designs the y frame square and j frame round.

To power source for all alternating current motors manufactured in accordance with standards adopted by the national electrical manufacturers association. The pump efficiency can vary between 10 and 80. Electric motor wire marking connections.